Basic requirements for sand for concrete

Source: Kefid Shanghai Machinery Views: 562

The concrete is a kind of artificial stone that is consisted by water, cement, stone(coarse aggregate) and sand (fine aggregate). Because of its wide material sources, good plasticity, simple processing, strong strength and durability and so on, it is widely used in the field of architecture. Sand has been applied to ordinary concrete, reinforced concrete and other projects, and is one of the most important raw materials in the construction market.

With the decrease of natural sand resources more and more mechanism sand is chosen for concrete preparation. But the preparation of concrete has the following requirements for the manufactured sand: first, the total surface area of the sand particles is small, in other words, the the sand is as thick as possible. In concrete, cement paste is effectively bonded through the surface of aggregate particles. The smaller the total surface area of aggregate is, the more economical the cement will be. Secondly, the grain gradation of sand is good. Particle size distribution refers to the matching of sand with different size. The size of sand particles is reasonable, which can be filled in step by step, reduce the void ratio, save cement, improve the density of concrete, and strengthen the strength and durability.

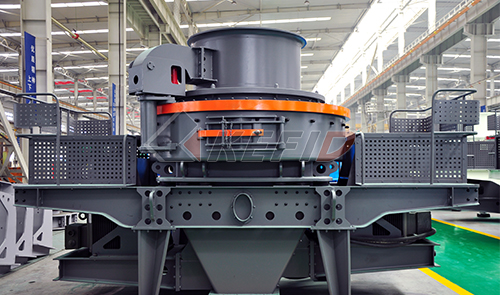

Excellent equipment is need to make high quality mechanism sand, Kefid recommend the Deep Rotor VSI Crusher, it has advantages of large amount of processing, high efficiency and good shape of product, and convenient to maintain, which can meet your various requirements.